Minimizing Air Seeder Damage to Peas

Varying fan speed did not impact seed germination, vigour or seed coat damage. Seed moisture was the primary factor that determined seed damage.

LARGER AIR SEEDERS (>60 ft) typically require higher air velocity for adequate seed distribution and to prevent plugging. As larger seeding equipment has become more common, there was a desire to know if greater fan speeds resulted in increased damage to pea seed and how seed moisture content might impact seed damage.

The objective of this research was to determine the effects of air seeder fan speed and pea seed moisture content on pea seed quality throughout seeding.

Pea seeds at three different moisture contents (dried to 11.4%, as received at 13.6% and wet at 15.1%) were run through a stationary air drill at three different fan speeds representing low (FSL), medium (FSM) and high (FSH) speeds.

Fan speeds were determined by using the manufacturer recommended speed as the FSM (4250 rpm), then varying the speed approximately 8% lower and higher to achieve FSL (3900 rpm) and FSH (4600 rpm), respectively.

A 65-ft, 2010 Bourgault Paralink hoe drill 3310 with a 6550 cart was used. This equipment contained six secondary manifolds, each with a total of 11 openers, resulting in 66 total openers across the drill. This air drill was selected out of a list of commonly used seeding implements in Manitoba since this configuration has the potential for

increased seed damage.

AAC Carver yellow pea seed was used, which has an average thousand seed weight of 240 g/1000 seeds representing an average pea seed size. The seeding rate in these trials was 222.7 lbs/ac (3.7 bu/ac), calculated to target approximately 7.4–8.4 live plants/ft2.

The fertilizer used was MES15 at a rate of 20 lbs P2O5/ac, resulting in 59.7 lbs/ ac of product. Each treatment was run for the equivalent of 0.5 seeded acres with a targeted ground speed of 3.0 mph. Germination, vigour and seed coat

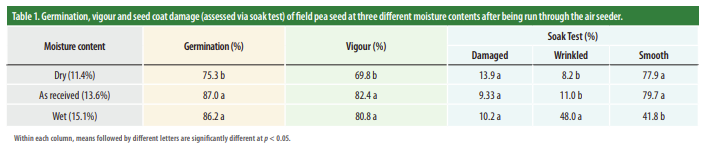

damage (via soak test) were assessed before and after treatments. Surprisingly, varying fan speed did not significantly affect seed germination, vigour or seed coat damage. Seed moisture was the primary factor determining seed damage (Table 1).

Seed moisture content had the most significant impact on germination, vigour and seed coat damage (percentage of damaged, wrinkled and smooth seed coats). Pea seed that had been dried to moisture contents below the recommended level (to 11.4% seed moisture) had significantly lower germination and vigour (more than 10% decrease) compared to the “as-received” seed (13.6% seed moisture) and the wet seed (15.1% seed moisture). Reduced germination and vigour will negatively affect plant stand and plant establishment, reducing crop yield potential. These results reflect similar findings from previous PAMI research on air seeder distribution and seed damage to wheat, canola and soybeans, where drier soybean seed (8% seed moisture) resulted in poorer germination than 13% soybean seed moisture.

Ensuring seed moisture content is at the recommended level is imperative for good seed germination, vigour and seed coat quality. These results indicate that initial moisture content, before running the seed through the drill, is an important factor for maintaining

seed quality and establishing a successful crop.

To obtain the desired moisture content, it is recommended to pay close attention to proper storage and to monitor pea seed moisture by moving the grain during storage, as necessary. However, some factors influencing seed moisture are not within our control. Though differences in fan speed did not affect the seed quality, manufacturer recommended speeds are suggested to maintain productive performance

to reduce the risk of plugging at low fan speeds and improve the potential for more accurate seed distribution at recommended speeds versus high speeds. Understanding the impact of seed moisture on germination and vigour translates to more accurate seeding rates and thus successful plant stands.