DURABILITY TESTING with mts® systems

Replicating real-world scenarios in a controlled laboratory setting.

We utilize the leading force and motion control testing equipment on the market. The FlexTest® Digital Controller and the MultiAxial Simulation Table (MAST) System made by MTS® defines and automates virtually any material, component, or structural test.

STRUCTURAL DURABILITY & FATIGUE TESTING

Access an assortment of hydraulic actuators and an MTS FlexTest® controller for customized structural lab testing. With this test equipment, we have the ability to perform a broad range of test control options from simple square wave and sinusoidal inputs to full simulation of complex field data with up to four independently controlled actuators. Our FlexTest controller has he ability to independently control up to four different hydraulic actuators, allowing up to four different test loads to be applied to the test sample simultaneously.

Structural durability and fatigue testing is performed by subjecting a test sample to the load conditions it will experience during its service life. This testing is typically performed early in the product development process to identify any design deficiencies prior to releasing the product for production. It is also commonly used as a qualification test for component selection or final product validation.

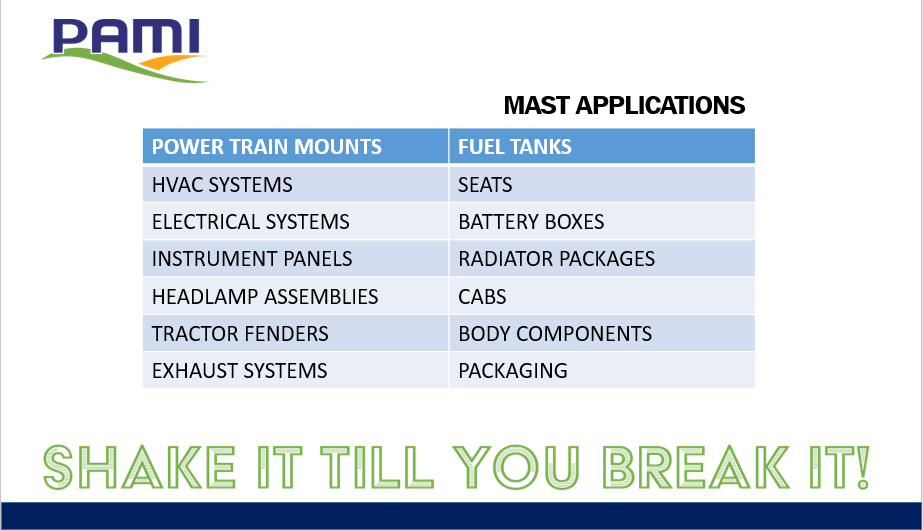

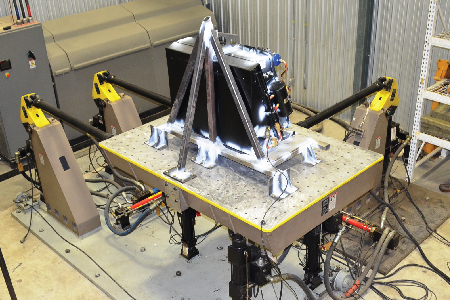

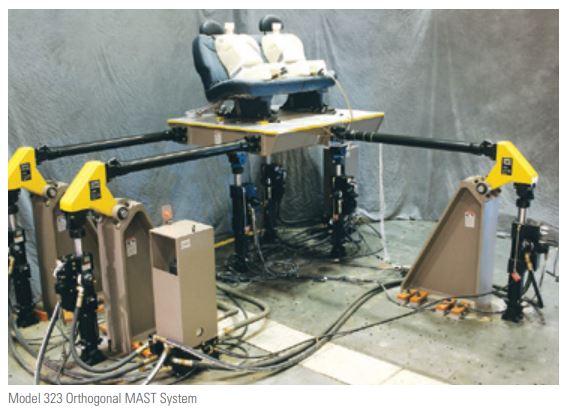

VIBRATION TESTING

Let's Shake Things Up!

Six degrees of freedom motion to produce a number of tests including sinusoidal, random, and field simulation tests. Our MAST system is ideally suited for testing ground based vehicle or machine components to evaluate how they will respond to vibration anticipated during operation, or transit, and to verify how the product is expected to survive through its entire life.

This testing is commonly performed on machine or vehicle components that will experience vibration loads throughout its service life. The test sample is secured to the platform of the shaker table using a test fixture or mounting system that is representative of its end-use installation.

CUSTOM TEST STAND DEVELOPMENT

We believe in supporting innovation. We work directly with you to develop, design and build custom test stands needed to support unique configurations of custom hydraulic cylinders, power train components and other mechanical systems. It is our goal to work directly with our clients one-on-one to advance industry.

WHY DURABILITY TESTING?

- Prevents over-design and saves on unnecessary materials costs.

- Improved product reliability reflected in increased customer satisfaction and fewer warranty claims.

- Require less time than field testing and gets products to market faster.

- Permits testing of isolated components to measure performance without machine interference.

- Is independent of environmental factors and precisely repeatable allowing for direct comparison of competing designs.

- Is an economical and convenient alternative to traditional methods.

- Validates computer modeling and simulation.

- All-weather testing – tests are done in the lab.

- Components can be tested without building or shipping an entire prototype vehicle or machine.

COMMON TEST SERVICES

- Structural Durability & Fatigue Testing

- Squeak & Rattle Testing

- Vibration Testing

- Roll Over Protective System Testing (ROPS)

- Falling Object Protective Structure Testing (FOPS)

- Seat & Seat Belt Anchorage Testing

- Rear Impact Guard Testing

Shortened testing cyle.

Compress lengthy testing into a shortened timeline allowing for quicker results, improved efficiencies and faster to market. Durability and fatigue testing is an economical and convenient alternative to traditional methods requiring less time than field testing which in turn gets products to market faster.

Prevent over-design and save on unnecessary material costs.

One of the primary advantages of utilizing durability testing is its ability to prevent over-design, which, in turn, helps save on unnecessary material costs. Traditional design methods often lean toward a conservative approach, leading to designs that are heavier and bulkier than required. By conducting detailed simulations, engineers can precisely determine the structural and functional requirements of a component or system, eliminating excess material usage.