Interested in getting a quote for your next project?

Electronics Lab and Cable Shop

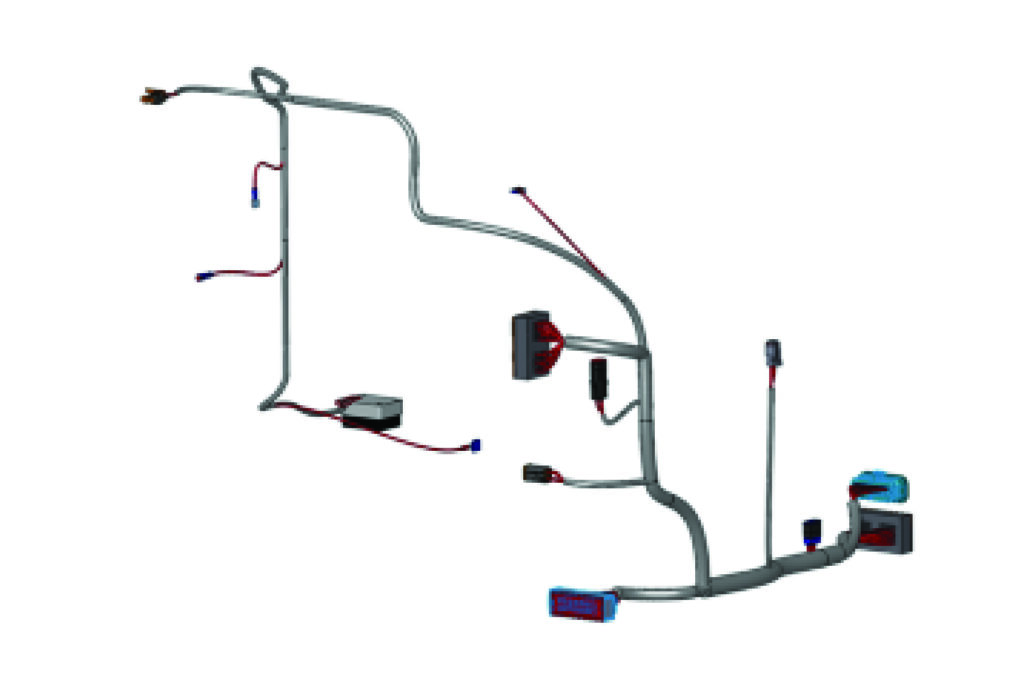

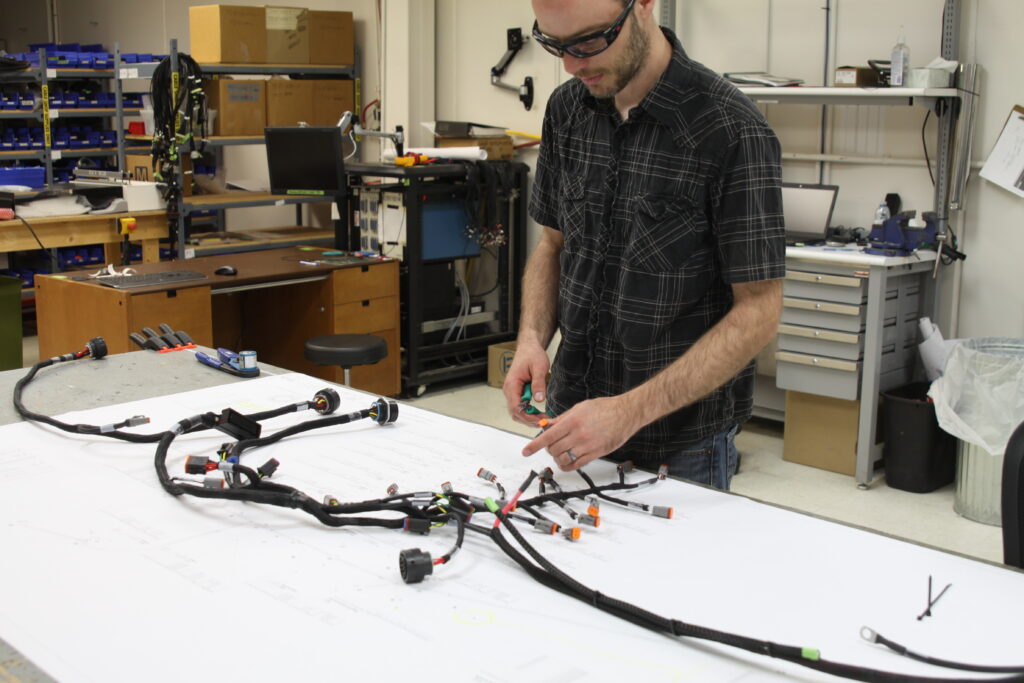

New products are designed and developed daily creating a need for high quality electronic prototypes. PAMI’s well equipped Electronics Lab and Cable Shop is rooted in technology using it’s suite of sensors, instrumentation, data acquisition equipment, and programmable logic controllers (PLCs) to acquire data for analysis, control other mechanical equipment and transfer information to operators. We’ve worked with OEM’s to design and manufacture custom wiring harness and control solutions for both new machines (from scratch) or add autonomous operation to existing machinery.

OUR CAPABILITIES

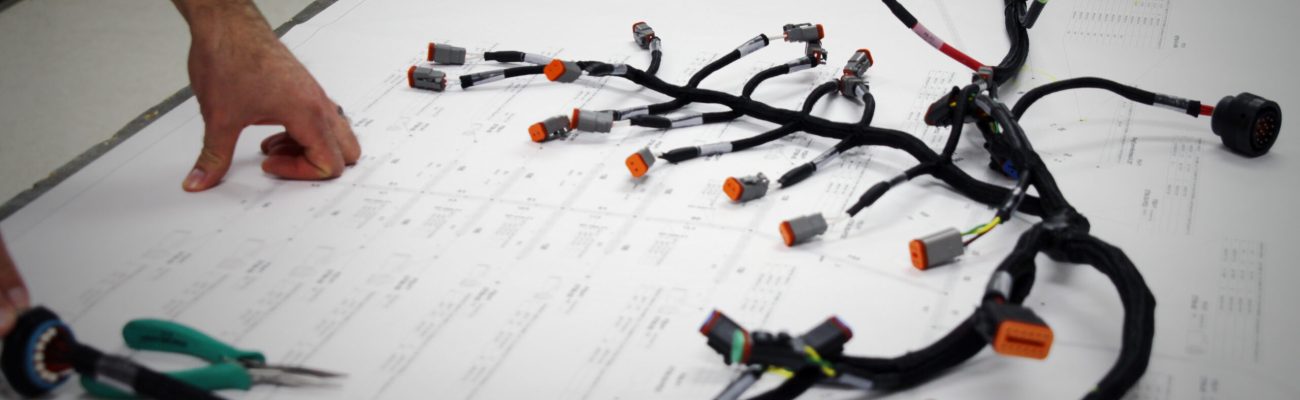

- Schematic and Harness Design (Zuken E3)

- Electro-Hydraulic Control Integration

- Custom Harness Prototypes

- CANBUS (J1939) Integration

- PLC and HMI Selection and Programming

- Panel/Junction Box Design/Build

- Harness Modifications / Re-engineering

- Documentation Packages

The PAMI Electronics Lab and Cable Shop contains various instruments and tools for building and maintaining electronic equipment and is well equipped to fabricate high quality, fully tested, prototype and limited production harnesses.

- 32 Carrier Wire Braider (textile or metal)

- Wire Cutter and Marker (Schleuniger PowerStrip 9550 M)

- High Potential (HPOT) Cable Tester (MPT 5000L)

- Pull Tester

- 3D Design and Modelling (Zuken E3)

- Vacuum Packaging

All cables and harnesses and electrical assemblies are thoroughly tested for quality using a HPOT cable tester to detect incorrect/missing pins, breaks in wires and improper splices prior to final braiding, sealing, and installing or shipping to the client ensuring they will perform as intended.

PAMI’s electronic lab contains various instruments and tools for building and maintaining electronic equipment such as oscilloscopes, meters, frequency generators, power supplies, computers, and soldering stations. Taking advantage of its shop facilities, PAMI can build and install whole control systems for mobile applications.