Interested in getting a quote for your next project?

Value Added Processing

Pilot-Scale Agricultural Production Solutions

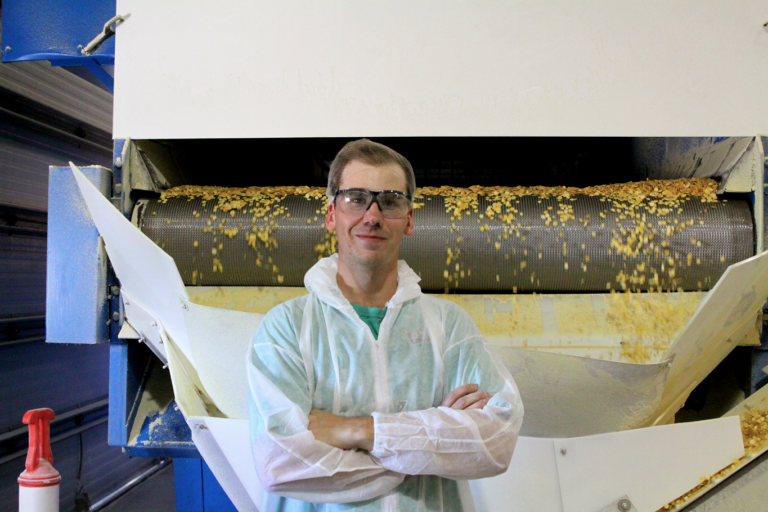

The Crop Processing Development Centre (CPDC), established in 1999 at PAMI’s Humboldt location, was specifically designed to offer processing companies a unique advantage: a secure, fully equipped, working-plant environment where they can conduct applied research, experiment with innovative processing techniques, or produce pilot product runs for market testing. This dedicated facility enables companies to explore the potential of value-added processing by refining raw agricultural products into more marketable items that meet consumer demands.

PAMI’s Crop Processing Development Centre is a large, adaptable facility, purpose-built to provide essential space for setting up and testing individual pieces of equipment, custom products, pilot-scale processes, or full-scale developed processes—all without disrupting ongoing production in the companies’ main facilities. This setup is especially valuable for those engaged in value-added agriculture processing, where raw agricultural products are transformed to significantly increase their value. This could include turning raw grains into flours, oils, proteins, or other ingredients that cater to specialized consumer needs, boosting profitability and expanding product offerings.

By leveraging the CPDC, companies can advance their research and development activities without impacting their current production workflow. This allows for rigorous testing and fine-tuning of new products and processes in a dedicated, risk-free environment. Once the equipment, product, or process is validated and refined within the CPDC, clients can confidently implement these innovations into their existing operations, ensuring a seamless integration of value-added processing strategies that enhance both product quality and market potential.

Sample Applications from the Crop Processing Development Centre

- Processing Testing, Validation and Optimization

- Commercial-Scale Processing Campaigns (500kg/hr to 1MT/hr)

- Batch Processing of Materials – De-hulling and Cleaning for Residue Testing

- Essential Oil Extraction

- Milling

- Drying

- Custom Products like Animal Feed, Fertilizer or Flour Blends

- Granulation or Pelleting

How PAMI Can Help

- Project Management

- Process Development & Modelling

- Equipment Investigation & Sourcing

- Equipment Testing

- Material Handling

- Process Scale-Up & Optimization

- Processing

- Labour & Resourcing

- Engineering & Shop Support

- Detailed Reporting

- Transportation & Logistics

- Certification & Document Support

Crop Processing Development Centre Features:

- Heated Processing Facility: 70′ x 185′

- Adjacent to large environmental chamber for extreme-temperature processing

- Adjacent to fabrication shop, allowing for efficient process modifications

- 600V and 208V three-phase electrical service with VFD controls

- 60hp, 250 psi boiler for process steam generation

- Dust Control System

- Storage bins on-site

- Material handling and processing equipment

- Pellet mill

- Air classifying mill

- Hammermill

- Belt dryer

- Dehuller

- Mixer

- Essential Oil extractor

- Hoppers and conveyors

- Interior liner and drainage trench for efficient cleanup

See Our Crop Processing development centre in Action

Partnering with You to Scale & Implement Your New Ideas

Engineered Solutions & Validation Testing Before Investment

Whether you are a new business venture who wants to prove your processing idea before investment or you have an existing process or machine that is not performing, we are here to help.

With almost 50 years of experience designing, building, and testing equipment and processes, we are well equipped to handle any problems. Our team of researchers, engineers, technologists, agronomists, and fabricators are passionate about bringing your ideas to fruition.