Limited Testing Window Not a Problem for Simulation Services

The world of agricultural and industrial design has come a long way from its genesis of template sketches and trial and error. A remarkable set of digital tools has evolved to design mechanical or fluid processes for use in mining, tillage, or harvesting efficiencies and a host of other applications.

The challenge for manufacturers and end users is to keep up with rapidly moving technology and offset the expense of purchasing hardware and software to get the job done. Designers need the support of people with expertise, passion and drive to share their vision and move the project from the drafting table to the practical stage.

Prairie Agricultural Machinery Institute and its engineers offer state of the art simulation design technology with engineering personnel who have the background and hard-wired imagination to listen to customers’ problems and collaborate on solutions.

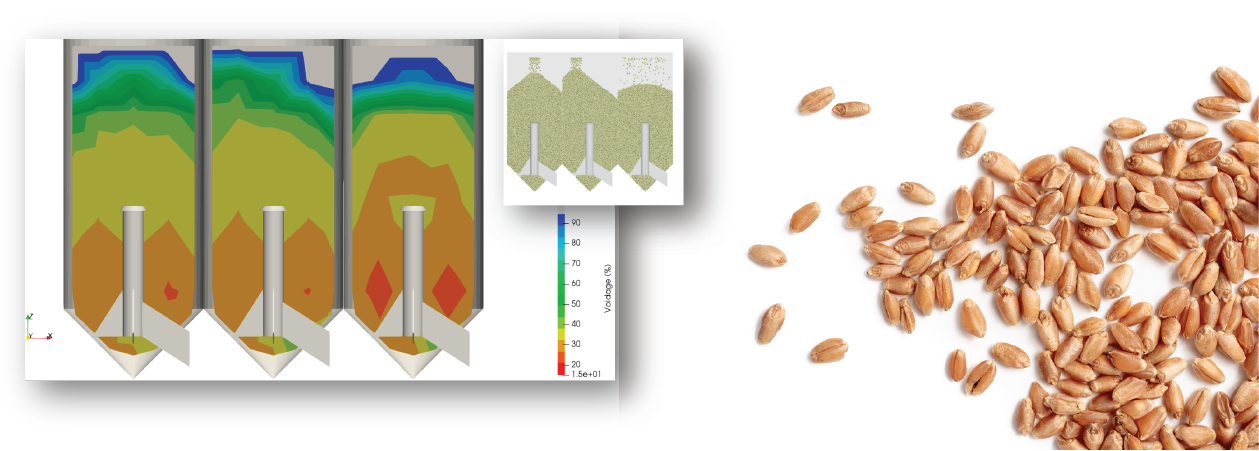

Some of those simulation tools come in the guise of Discrete Element Modeling (DEM), a technology and study of particulate flow with elements that can be resized to simulate anything from miniscule soil particles to larger coarser components like grains.

Samuel Ferré is a key engineer in the application of this technology. It takes the know-how and the vision of a professional like Ferré to meld the digital software to the project. Ferré explains that the adaptability of the particulate size in the DEM simulation makes it a perfect solution for a range of applications.

“It can be tailored to whatever a client might be looking to investigate,” Ferré details. “The study of the physics and impact of small spheres interacting, which can be scaled to just about any level. If for instance, we were curious about the study of wheat flow, or any sort of granular flow, you could create a wheat particle out of multiple spheres. You’d would then replicate many of them until you created a flow like in an auger or the cleaning system in a combine.”

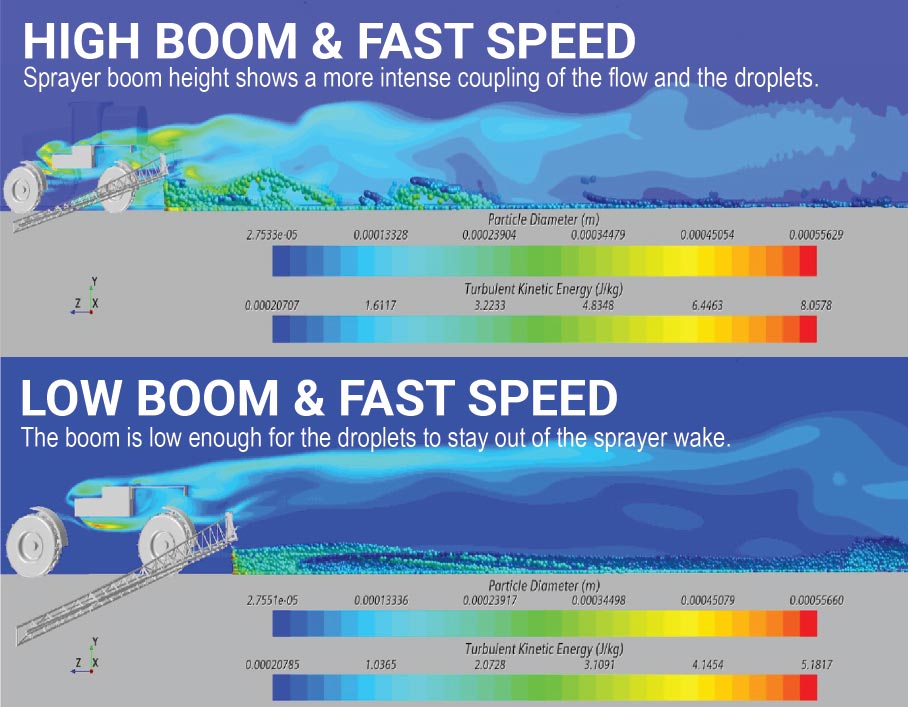

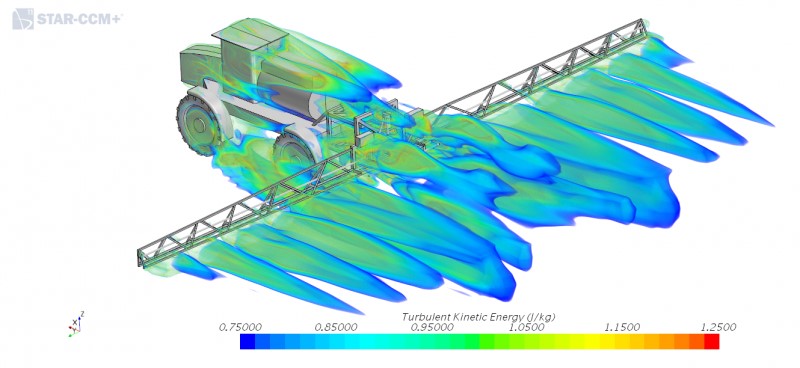

It’s that same curiosity and innate drive to know and problem solve that prompted Ferré to stretch his digital repertoire into other types of modeling: Computational Fluid Dynamics (CFD), Multi-Body Dynamics (MBD) and Finite Element Analysis (FEA). “When appropriately applied, these numerical modeling tools provide a valuable insight into design aspects that would not normally be available with traditional engineering techniques.”

Elements in a simulation can be reduced from grain sized units to small microparticles replicating soil components. We use it to test compaction or flow behaviours, in effect going from a grain bin to a virtual sand or soil box.

The limited growing season on the Canadian prairies makes for equally limited windows in which to traditionally test equipment for seasonal practices. That’s not a problem when virtual models can be created to test various properties throughout the year. An overly wet field or a frozen or compacted soil bed won’t be a barrier to carrying out simulated tests.

“During a past project, a client was looking to improve an implement before the upcoming season. Several design ideas were in question, and limited resources were available. While working with the client, we developed a virtual model and evaluated and compared numerous designs. This allowed a narrowed scope during the physical testing season and reduced costly trial and error iterations.”

With the right monitoring and data, Ferré can model conditions of a field right down to density and particulate matter, thereby recreating conditions found in a particular plot of soil. After Ferré has simulated the digital soil bin, he can test various digital tool designs and pit them against the conditions the tools are going to work in. The process can be used to sort and sift before presenting the client with the best design options.

“You create the virtual soil bin, run the test, study the data, and adjust the virtual bin until it aligns with the initial field tests that were conducted. Following that, you look at various product designs and compare their efficacy relative to the baseline.”

Using the modeling, there’s no waiting for seasonal shifts, optimal moisture content or specific conditions. The environment can be manipulated digitally to save time, money and unnecessary mechanical prototypes.

Ferré acknowledges that simulation modeling may not be able to completely replace real-world testing, but it has great value in the design process and in troubleshooting. The methodology is also useful in analyzing competitors’ designs to see what components are better or worse.

“I usually revert back to the basics and fundamentals of the engineering design process – define the problem and objectives, research relevant information, propose solutions, test and evaluate, and communicate the results.”

For testing and evaluations, simulations play a key part. Throughout that phase, Ferré works in close connection with the client, delivering information and taking input on each step. His strength lies both in his commitment to the client’s needs and his staunch support from and for his colleagues at PAMI.

“I am a strong advocate for PAMI’s mandate to help clients improve their products and processes. PAMI is uniquely positioned to provide cost-effective numerical modeling services. This specialized software can be cost prohibitive for most companies not wanting to invest in a full-time simulation team.”

It’s Ferré’s passion for the processes and the technologies that has led him to delve into available software and modelling formats in addressing a wide range of applications in agricultural and related industries. For him, it’s about meeting clients’ and end users’ needs.

“I am quite passionate about the engineering and simulation fields,” Samuel asserts. “I enjoy interacting and assisting clients with their continually changing needs. Any improvements and contributions will tend to trickle down to the end user. Knowing that my involvement eventually helps local producers and consumers is very satisfying and motivating.”

Ferre is quick to share credit with his colleagues for their passion, interest and evolving expertise. He says the kind nature, intelligent exchanges and driven attitude make his colleagues great people to work with.

In the end, Ferré’s allegiance to PAMI has to do with the variety and nature of the work, and the fact that PAMI is on the cutting edge of innovation. Ferré confesses an affinity for the agriculture side, but he enjoys applying his expertise in the mining and transportation fields as well.