Interested in getting a quote for your next project?

Modeling & simulation services

Optimize Designs with Finite Element Analysis, Discrete Element Method, and Computational Fluid Dynamics

Simulation is the process of creating a virtual or mathematical model of a real-world system, scenario, or process to study its behavior under different conditions. It allows users to test, analyze, and predict outcomes without the risks or costs associated with real-life experimentation. Our advanced simulation team uses the Altair Package and Siemens’ StarCCM+ Software to include simulation work in the realm of Discrete Element Method, Finite Element Analysis, Computational Fluid Dynamics, Fluid Structural Interactions, and Multi-Body Dynamics.

Enhance your manufacturing process with advanced modeling and simulation. Our software suite transforms concepts into reality faster and more efficiently. Leverage finite element analysis, discrete element method, computational fluid dynamics, and multi-body simulation tools to optimize designs. Utilize integrated analytics and machine learning for data-driven decisions and access a comprehensive material database to meet performance and sustainability goals. Solve real-world problems with technology that enables testing and design alterations.

Numerical modeling can play a significant and effective role when appropriately applied in the design cycle. Varying levels of modeling can be customized for your needs.

- Reduce Production Material Costs

- Test products in the off-season

- Simulation Extreme or Dangerous Conditions

- Reduce Risk

- Faster product to market cycles

- Determine Failure Points

- Cost Effective Prototyping

- Time Efficiency

- Failure and Warranty Claim Investigations

- Part & Component Optimization

- Initial Concept Comparisons

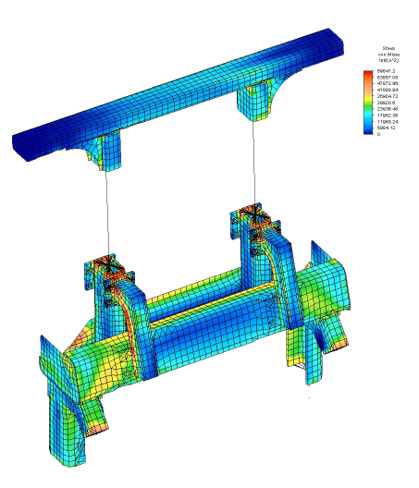

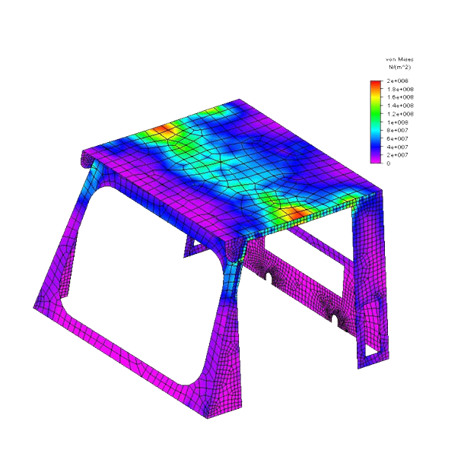

Finite Element Analysis - Identifying points of failure.

Finite Element Analysis is a powerful tool for predicting how a product will react to real-world forces, heat, vibration, fluid flow and other physical effects. Finite Element Analysis shows whether a product will break, wear out or work as it was intended.

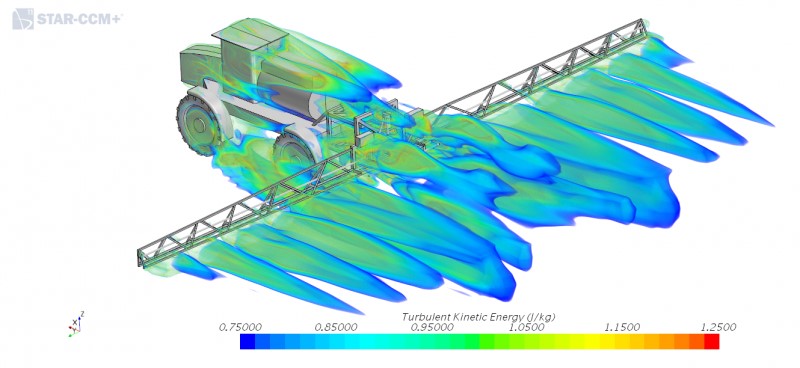

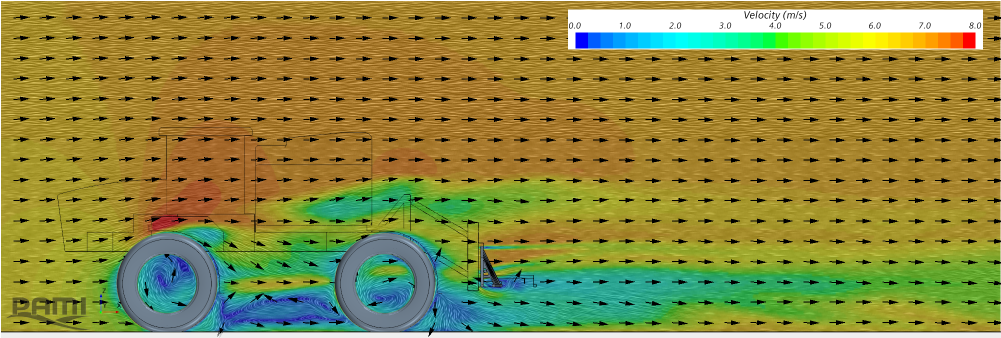

Computational Fluid Dynamics - Looking at efficient flow.

Computational Fluid Dynamics is a branch of fluid mechanics that uses numerical analysis and data structures to analyse and solve problems that involve fluid flows. The interaction of fluids with surfaces can be extremely important when finding efficiencies in the manufacturing process.

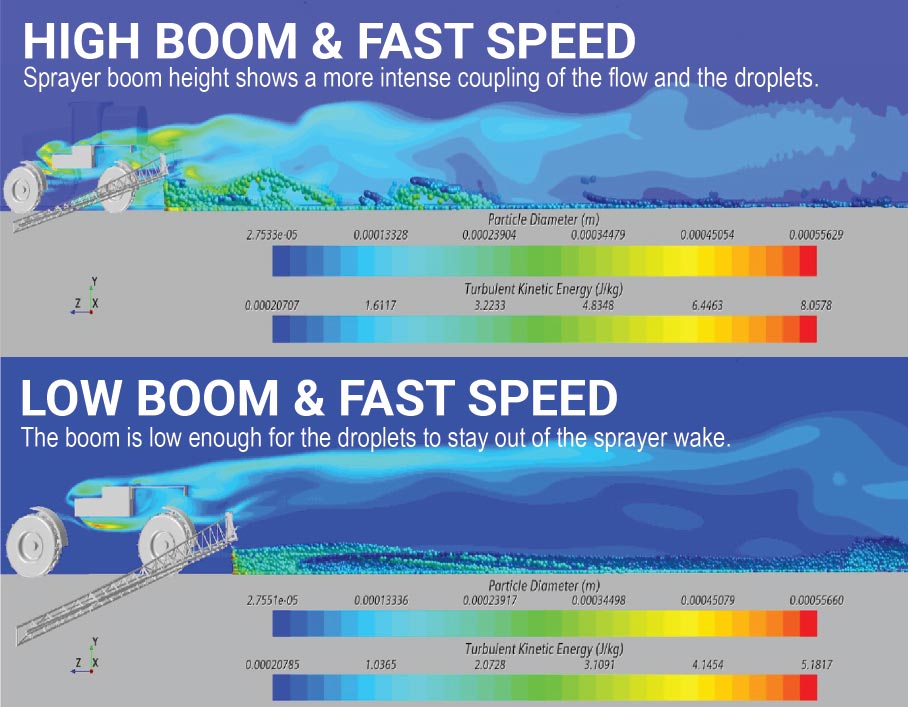

The team at PAMI partnered with Western Grains Research Foundation to study spray drift. This project’s aim was to gain further understanding of the operational parameters affecting pesticide drift on the Canadian Prairies. High-clearance sprayers have become large machines that are operated at relatively high speed. A better understanding of their aerodynamic properties is required to maintain the high productivity of large sprayers while minimizing spray drift.

The effect of high-clearance sprayer operational choices, namely travel speed and boom height, were thoroughly investigated using a variety of numerical and experimental methods.

This project combines computational fluid dynamics (CFD) modeling with field trials to enhance our understanding of the drift potential created by the conditions under which the spray is released. The impact of the airflows resulting from the movement of the sprayer are considered. In relation to field trials, multiphase CFD modeling is being developed to investigate the behaviour of the spray as affected by the forces (airflows) that exist when it is released from the nozzles.

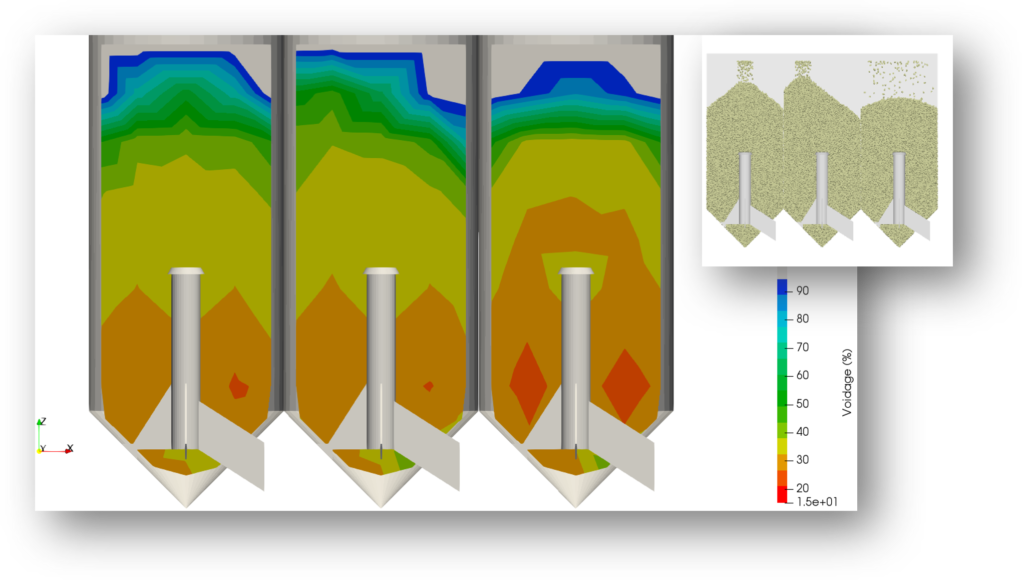

Discrete Element Method - Motion and effect of particles.

Discrete Element Method is the method of computing the motion and effect of a large number of small particles. Modeling the bulk behaviour of particles is particularly important in agriculture innovation. Understanding how grain will react in storage or how soil will react using a specific implement can advance technology and bring safe and effective products to market quicker. In mining, understanding how product flows on conveyors can lead to efficiencies and alterations helping reduce wear and control dust particles.

“The world of agricultural and industrial design has come a long way from its genesis of template sketches and trial and error. A remarkable set of digital tools has evolved to design mechanical or fluid processes for use in mining, tillage, or harvesting efficiencies and a host of other applications.

The challenge for manufacturers and end users is to keep up with rapidly moving technology and offset the expense of purchasing hardware and software to get the job done. Designers need the support of people…” – READ MORE

Simulation - Complex predictive analysis.

HAVE QUESTIONS?

complete the following form and Submit.